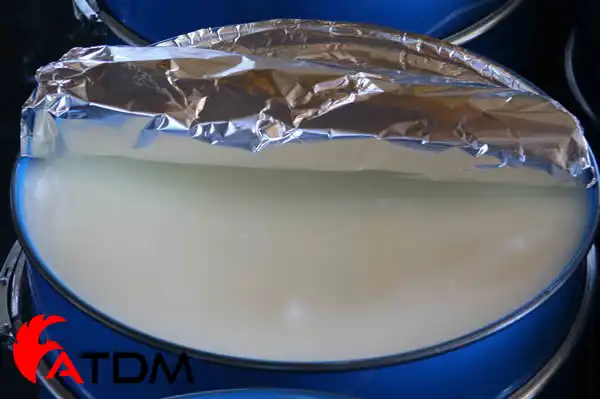

Petroleum jelly, commonly known as Vaseline, is a semi-solid hydrocarbon material refined from petroleum streams and used across industrial, pharmaceutical, and formulation-based applications. It matters because it provides reliable moisture resistance, surface protection, and mild lubrication without reacting with most materials. Engineers, manufacturers, and procurement teams rely on this material when stability, purity, and predictable behavior matter more than branding.

In professional supply chains, petroleum jelly is treated as a refined technical material, not a consumer product. Producers derive it from paraffinic and microcrystalline fractions and then purify it to achieve controlled consistency, color, and chemical neutrality.

From a functional perspective, this material offers:

Table of Contents

ToggleSemi-solid structure over a defined temperature range

Strong resistance to water and humidity

Compatibility with metals, elastomers, and many polymers

These properties explain its presence in industries that otherwise share little in common.

A common sourcing error is assuming all grades of petroleum jelly perform the same. In reality, each category targets a different risk profile.

Industrial users select this grade for performance rather than appearance. Typical applications include:

Moisture barriers in cable systems

Corrosion protection on terminals and fasteners

Light mechanical lubrication

Rubber and plastic processing aids

Color and odor tolerance remain flexible as long as stability remains consistent.

Personal-care manufacturers require tighter control of color, odor neutrality, and texture. Consistency and oil retention matter more here than extreme thermal resistance.

Medical applications demand compliance with pharmacopeia standards such as USP, BP, or EP. Pharmaceutical petroleum jelly undergoes deeper refining to remove trace aromatics and ensure toxicological safety.

Experienced buyers never order based on name alone. They compare specifications.

Softening and flow temperature determine whether the material remains stable during transport or use in warm climates.

Softer grades spread easily, while firmer grades stay in place under pressure.

Low oil bleed matters in cables, seals, and formulations where migration can cause failures or cosmetic defects.

Some applications tolerate yellow tones, while regulated industries require high whiteness and resistance to discoloration.

Manufacturers use petroleum jelly as a filling compound to block moisture ingress. Long-term stability matters more than initial appearance.

Processors apply controlled amounts as a conditioning aid. Stable oil balance prevents surface defects during extrusion or molding.

Technicians apply thin layers to exposed metal parts, battery terminals, and tools to slow oxidation without forming hard residues.

Approved grades support gasket lubrication and sealing in regulated packaging environments.

Although both originate from petroleum refining, they serve different roles.

| Property | Petroleum jelly | Paraffin wax |

|---|---|---|

| Physical form | Semi-solid | Solid |

| Flexibility | High | Low |

| Oil content | High | Low |

| Sealing ability | Excellent | Limited |

They are not interchangeable without reformulation.

Reputable suppliers test petroleum jelly using standardized methods, including:

ASTM tests for penetration and softening behavior

Color scale evaluation

Oil separation and aging stability

PAH analysis for sensitive applications

In real supply chains, consistency between batches often matters more than marginal laboratory improvements.

Despite its stability, improper handling causes issues.

Store in sealed containers away from contamination

Avoid prolonged exposure to excessive heat

Do not mix batches without compatibility checks

Use clean tools during melting or transfer

In hot regions, buyers typically request higher-stability grades.

From industry experience, problems usually arise when buyers:

Order by name instead of specification

Ignore oil separation data

Use industrial material in regulated applications

Assume all white material meets medical standards

Clear technical alignment prevents costly rejections.

Beyond the material itself, supplier expertise affects outcomes. ATDM supports buyers by matching petroleum jelly grades to application conditions, compliance needs, and climate exposure rather than offering a single generic option.

Petroleum jelly remains widely used because it delivers predictable sealing, protection, and lubrication performance across many industries. It works best where moisture resistance, chemical neutrality, and long-term stability matter.

Before purchasing, define your application clearly, review specifications carefully, and test under real operating conditions. Matching grade selection to actual use is the most effective next step.