Limestone powder is a finely ground calcium carbonate material used as a functional raw input in construction, manufacturing, chemicals, and process industries where consistency, purity, and cost control matter. It improves workability, strength, and stability in cement and concrete, acts as a filler or extender in polymers and paints, and supports chemical reactions in environmental and metallurgical processes. Buyers who need predictable performance, stable supply, and controlled particle size such as manufacturers, engineers, and procurement teams—use limestone powder to optimize both product quality and operating costs.

What Limestone Powder Is Made Of and Why It Matters

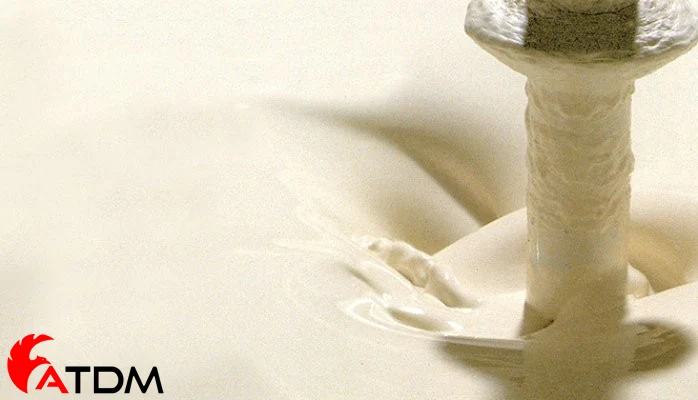

Producers manufacture limestone powder by crushing and milling natural limestone rock with high calcium carbonate (CaCO₃) content. The key value comes from particle size distribution, purity, and moisture control, not just the chemical formula.

In real applications, these factors decide:

- What Limestone Powder Is Made Of and Why It Matters

- Typical Industrial Grades and Specifications

- Key Industrial Applications and Real-World Use

- Handling, Storage, and Transport Considerations

- Common Buyer Questions We See in Practice

- Limitations and When Limestone Powder Is Not Ideal

- Quality Control and Supplier Reliability

- Conclusion: Is Limestone Powder Right for Your Operation?

How well the powder disperses in a mix

Whether it reacts as expected or remains inert

How it affects strength, viscosity, or surface finish

Engineers rarely ask, “Is it limestone?” They ask, “Will this grade behave the same every batch?”

Typical Industrial Grades and Specifications

Suppliers usually offer limestone powder in multiple fineness levels, from coarse fillers to micronized grades. Buyers should confirm specs against their process needs rather than relying on generic labels.

Common technical parameters include:

CaCO₃ content: often 95–99% depending on quarry source

Particle size (D50 / mesh): affects flow, reactivity, and surface area

Whiteness / brightness: critical for paints, plastics, and paper

Moisture: low moisture improves storage and dosing accuracy

Many industrial buyers reference ASTM C25, ASTM C110, or ISO calcium carbonate standards to align quality expectations across suppliers.

Key Industrial Applications and Real-World Use

Construction and Cement

Concrete and dry-mix producers use limestone powder to improve particle packing, reduce cement consumption, and enhance workability. When matched correctly, it lowers cost without sacrificing compressive strength.

Practical note: Overly fine material can increase water demand. Mix design testing matters more than brochure claims.

Plastics and Polymers

Manufacturers add limestone powder as a filler in PVC, PE, and PP compounds to control cost, stiffness, and surface finish.

What processors watch closely:

Consistent particle size to avoid screw wear

Surface treatment compatibility

Stable color batch to batch

Paints, Coatings, and Sealants

Formulators use calcium carbonate powder to control opacity, viscosity, and film strength. Fine grades support smooth finishes, while coarser grades improve bulk and durability.

Chemical and Environmental Uses

In flue gas treatment, water purification, and acid neutralization, limestone powder acts as a reactive alkali source.

Operational insight: Reactivity depends on surface area and purity, not just CaCO₃ percentage.

Metallurgy and Other Process Industries

Steel and glass producers use limestone powder as a flux to remove impurities during high-temperature processing.

Handling, Storage, and Transport Considerations

Industrial users often overlook logistics until problems appear.

Best practices include:

Store in dry, covered conditions to prevent caking

Use sealed bags or silos to control moisture pickup

Confirm bulk density for accurate dosing and freight planning

Fine powders can generate dust, so plants usually apply standard dust control and PPE measures.

Common Buyer Questions We See in Practice

From experience supplying industrial markets, these questions come up repeatedly:

Will this grade behave the same in continuous production?

How stable is the source quarry over time?

Can you provide consistent COA and particle size reports?

Does this material meet our local or export standards?

Reliable suppliers answer these before the first shipment, not after a problem.

Limitations and When Limestone Powder Is Not Ideal

Limestone powder does not suit every application. It reacts with strong acids, and lower-purity grades can introduce unwanted minerals. In high-performance or specialty formulations, engineers sometimes need precipitated calcium carbonate or alternative fillers instead.

Honest evaluation at the trial stage saves time and rework later.

Quality Control and Supplier Reliability

Industrial buyers should expect:

Regular Certificate of Analysis (COA)

Clear specification ranges, not single “typical” values

Traceability to quarry and processing line

At ATDM, limestone powder supply focuses on consistent industrial grades and documented quality control rather than commodity spot trading, which helps buyers plan long-term production.

Conclusion: Is Limestone Powder Right for Your Operation?

Limestone powder fits operations that need a reliable, cost-effective mineral input with predictable performance. It works best when buyers select grades based on application data, not price alone. Reviewing particle size, purity, and handling requirements upfront leads to smoother production and fewer surprises.

If you evaluate limestone powder for a specific formulation or process, the next step should be matching technical specifications to your application and confirming supply consistency before scaling up.