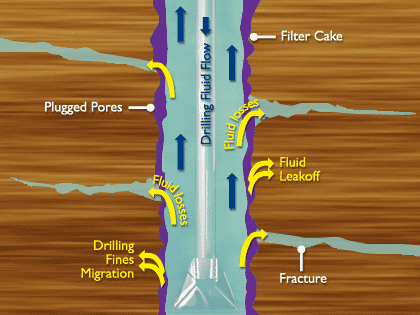

In the drilling of oil Wells, gas Wells, and the like, the process of pumping a drilling fluid through the well hole to and from the bottom is referred to as circulation. The maintenance of circulation of the drilling fluid is essential to successful drilling by the rotary method. The drilling fluid or mud is supplied at the surface of the well in large earthern pits or metal tanks and is pumped from these into the bore hole through the drill pipe and the drill bit to the bottom of the hole. ‘The mud returns to the surface between the drill pipe and the bore hole wall, bringing with it the drill cuttings. The circulation of the mud serves not only to carry the cuttings to the surface but also to cool and lubricate the drill bit, thus making possible the further effective penetration of the bit into deeper.

The formation in which the well is being drilled often contains cracks, fissures, cavities orstrata of high velocity. When the drill enters strata containing such, crevices, the mud flows away through the crevices to create the condition called lost circulation. Drilling cannot continue under conditions of lost circulation because the cuttings soon pile up around the bit and lock the bit and drill stem in the hole. Severe cases of lost circulation may require complete abandonment of the Well or so increase the cost of drilling that the well becomes uneconomical.

Table of Contents

ToggleIn conventional drilling operations, an aqueous bentonite drilling mud is used until a condition of lost circulation occurs, whereupon a filling material is mixed with the mud and carried by it into the crevices to, seal of leaks in the formation.

The gilsonite to be used in any particular case is selected from among the several available varieties so as to possess desired degrees of toughness and elasticity and a desired softening temperature, and then his crushed and screened or otherwise preformed so as to obtain it in the form of solid granules having various sizes and size distributions suitable both for sealing the crevices occurring in the well formation and for being easily placed and kept in suspension in an aqueous liquid carrier used to carry it into the bore hole and force it into the crevices therein. In general, the gilsonite here used consists nearly entirely of granules of sizes retained on a mesh screen, not more than about 10% of the particles being of any smaller size, and a major proportion of the granules have sizes in the range of minus 4 to plus 50 screen mesh. The coarsest particles present in the gilsonite-added to a drilling mud must be capable of passing through the mud pump used at the Well.

Having thus provided a suitable granular form of gilsonite, losses of circulation can be stopped pursuant hereto by simply mixing the granules of gilsonite with a portion of the aqueous drilling mud usually circulated through the bore hole and pumping the resulting suspension into the hole so that the mud will carry the gilsonite granules to the leaking strata and force them into the crevices therein. aqueous cement slurry or even clear water can be used as the liquid carrier, instead of the usual drilling mud.

It is necessary, however, that the carrier be an aqueous 50 pounds per barrel of the mixture or suspension. Forsevere conditions, this concentration may be increased to as much as 100 pounds per barrel.In some cases of lost circulation the use of a liquid l carrier is not necessary; for example, where circulation is lost by reason of cavities in the formation at a rela- If desired, a conventional tively’shallow drilling level. In such cases, the granular gilsonite may be simply poured into the bore hole in a loose or dry form and then forced into the cavities and connecting cracks by subjecting it to hydraulic pressure from-a conventional drilling mud or other liquid pumped over it.