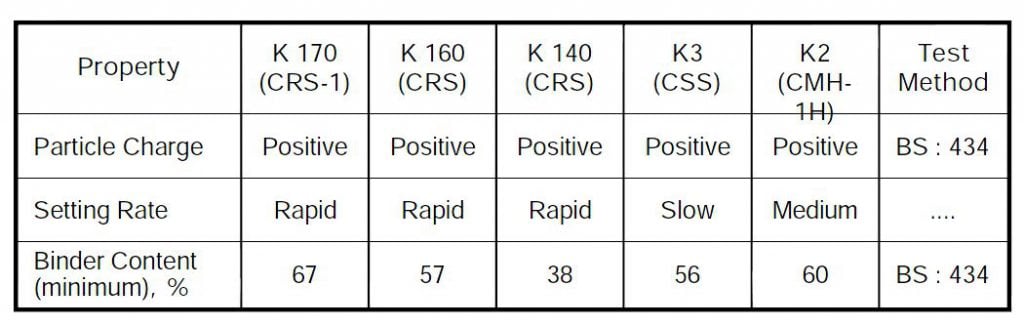

Bitumen K 170 (CRS1) K 160 (CRS) K 140 K 3 ( CSS) K2 (SMH1H) are emuslion bitumen.One of the method for modifying bitumen is emulsification with water which enhance bitumen properties incredibly. Another advantages of modification is that it can be applied cold (80°C). Emulsion bituminous asphalt consist of two immiscible liquids which are stabilized by emulsifier. They usually used for tack coats, hot-mixed asphalt, prime coats, chip seal. Firstly Anionic emulsion were developed and because cationic emulsion has more adhesion properties they are more favored especially in tack coating. The type (chemistry) of the emulsifying agent used, determines the designation. During application, the water in a bitumen emulsion is either lost by evaporation, or it may separate from the bitumen because of the chemical nature of the surface to which the emulsion is applied. This process is referred to as breaking.

Depending on the type of emulsifier the bitumen particles can be both positive and negative. Emulsions in which the bitumen droplets are negatively charged are called anionic emulsions. While, Emulsions in

Table of Contents

Togglewhich the particles are positively charged are called cationic emulsions.

Bituminous asphalt emulsion grades K 170 , 160 ,140 , is a rapid setting cationic asphalt, which has positive charge leading reaction between the emulsion and pavement. It contains 67% bitumen . 1 denoted as rapid braking. The primer bitumen which is used for emulsification is obtained from crude oil.

The main applications asphalt emulsion K1 -70 are surface treatment, sand seal and tack coat.

Treatments and seals:

Penetration macadam

* Bitumen K 160 may be used as a tack coat in special cases where night construction or high humidity exists.

Cationic emulsions may be used at ambient temperatures with aggregates, which need not be completely dry. Emulsions are less hazardous to use and can be applied in a wider range of conditions.

Emulsion Bitumen K1-70 cationic bitumen emulsion can be used at the ambient temperature at the spray rate of 0.25 to 0.70 litre per square meter (0.05 to 0.15 gallon per square yard)

Bitumen Emulsion K1-70 is available in:

Bitumen Emulsion is made up of three basic ingredients which include Bitumen, an emulsifying agent and water. Bitumen emulsion grade K 170 (CRS1) K 160 (CRS) K 140 K 3 ( CSS) K2 (SMH1H) containing minimum diffent percent of Bitumen, is commonly used for Tack-Coating. It is a medium viscosity cationic rapid-set bitumen emulsion used mainly for tack coating in normal overlay and patching work. Bitumen K 170 bitumen emulsion can also be used in grouting. Bitumen Emulsion K170 cationic bitumen emulsion is made according to KS 02-769: 1990 standard.

| No | Property | Result |

| 1 | Particle charge | Pos. |

| 2 | Residue on 710 um KS sieve (%)(m/m), maximum | — |

| 3 | Residue on 150 um KS sieve (g per 100 mL), maximum | — |

| 4 | Binder content (%)(m/m), minimum | 67 |

| 5 | Viscosity (degrees Engler (°E) at 20°C | — |

| 6 | Viscosity redwood No. II (s at 85°C) | 25-35 |

| 7 | Storage stability (long period test) % water content difference, maximum | — |